Vega D91 Profibus PA Bedienungsanleitung

Stöbern Sie online oder laden Sie Bedienungsanleitung nach Ausrüstung Vega D91 Profibus PA herunter. VEGA D91 Profibus PA User Manual Benutzerhandbuch

- Seite / 36

- Inhaltsverzeichnis

- LESEZEICHEN

- Operating Instructions 1

- Safety information 2

- Note Ex area 2

- Contents 3

- 1 Product description 4

- 1.2 Types and versions 5

- Product description 6

- 1.3 Technical data 7

- Operating conditions 9

- Transmitter housing 11

- Isolating diaphragm 11

- Process connections 12

- Processing unit 13

- 2 Mounting 14

- 3 Electrical connection 15

- Electrical connection 16

- 121110231 17

- Adjustment elements 19

- Menu schematic 20

- 1) 1) 1) 1) 21

- Adjustment 22

- Adjust PA output 22

- Evaluation 23

- Additional functions 24

- Sensor Sensor Sensor Sensor 25

- Sensor configuration 26

- Correct 30

- Pointer functions 31

- Simulation 31

- Display of measured values 32

- 5 Diagnostics 33

- 6 Instrument modification 34

- ISO 9001 36

Inhaltsverzeichnis

pLevel and PressureOperating InstructionsHydrostatic pressure transmitterD91 (Profibus PA)PROF IBUSPROCESS FIELD BUS0 - 20 bar

10 Pressure transmitter D91 (Profibus PA)Product descriptionAdditional temperature influence of isolating diaphragmsProcess connection Temperature coe

Pressure transmitter D91 (Profibus PA) 111.5 DimensionsTransmitter housingø 7667ø 41,64663ø 41,693ø 41,64690Product descriptionTube isolating diaphrag

12 Pressure transmitter D91 (Profibus PA)Process connectionsStandardStandardCooling elementD = outer flange diameterb = flange thicknessk = diameter o

Pressure transmitter D91 (Profibus PA) 13Product descriptionM20x1,538 8213510811885∅513013972100with protective coverProcessing unitwith display modul

14 Pressure transmitter D91 (Profibus PA)Mounting2 Mounting2.1 Mounting instructionsThe pressure transmitter can be mounted inany position. Cable entr

Pressure transmitter D91 (Profibus PA) 15Electrical connection3 Electrical connection3.1 Connection instructionsThe electronics in pressure transmitte

16 Pressure transmitter D91 (Profibus PA)Electrical connection3.2 Wiring plan-PA+PATransmitterE21PAAM10121110231OKTransmitterTransmitterZum Anschluß a

Pressure transmitter D91 (Profibus PA) 17onoffAddressHS12345678onoffAddressHS123456781+4+32=371 2 4 81632 64 128valueAd-just-mentCalcu-lationSimula-ti

18 Pressure transmitter D91 (Profibus PA)-PA+PATransmitterE21PAAM10121110231OK0 - 20 barSetupFurther adjustment steps (adjust PA output,adjustment etc

Pressure transmitter D91 (Profibus PA) 19Depending on parameter:change value (increase) orchoose out of a listChoose menu item or interruptadjustmentD

2 Pressure transmitter D91 (Profibus PA)Safety information, note Ex areaSafety informationPlease read this manual carefully, and also takenote of coun

20 Pressure transmitter D91 (Profibus PA)SetupMenu schematicAdjust-mentCalcu-lationSimula-tionOperate0,0skalEscapeAdjustwithpres.Adjustwithoutpres.Esc

Pressure transmitter D91 (Profibus PA) 21SetupAddi-tionalfunct.EscapeSensordataLan-guageEnglishResetP max15,0barTemp.30,7°CFabr.date49.98P min-0,3barR

22 Pressure transmitter D91 (Profibus PA)Adjustment(only possible, if "%" or "Lin%" has been cho-sen for the PA output)Adjustment

Pressure transmitter D91 (Profibus PA) 23Setupti1sAdjustment without taking the currentpressure into account (dry adjustment)Adjustment without pressu

24 Pressure transmitter D91 (Profibus PA)Setup1)The min. and max. values can be set to the actualvalue by pushing the "+" and "–"

Pressure transmitter D91 (Profibus PA) 25Setup4.3 Setup with adjustment softwareVEGA Visual Operating (VVO)VVO connection to the bus cableTo operate t

26 Pressure transmitter D91 (Profibus PA)SetupIf you have already connected several VEGAsensors to the bus, you can select the sen-sor to be configure

Pressure transmitter D91 (Profibus PA) 27In the window "Modify meas. loop configura-tion" you can assign a name and a descrip-tion to the me

28 Pressure transmitter D91 (Profibus PA)If you want to carry out the "Adjustment tak-ing the actual product into account" (liveadjustment),

Pressure transmitter D91 (Profibus PA) 29SetupClick in the window "Conditioning" to Lineari-sation.In the window "Linearisation" y

Pressure transmitter D91 (Profibus PA) 3ContentsContentsSafety information ... 2N

30 Pressure transmitter D91 (Profibus PA)Click in the window "Offset correction" toCorrect.Confirm the question with OK, in case theconditio

Pressure transmitter D91 (Profibus PA) 31Choose the requested measurement loopand click to OK.SetupPointer functionsClick in the window "Instrume

32 Pressure transmitter D91 (Profibus PA)SetupDisplay of measured valuesThe current values of the measurement loopscan be displayed from the main menu

Pressure transmitter D91 (Profibus PA) 33Diagnostics5 Diagnostics5.1 MaintenancePressure transmitters D91 are maintenance-free.5.2 Failure rectificati

34 Pressure transmitter D91 (Profibus PA)Instrument modification6 Instrument modification6.1 Exchange of adjustment mod-ules in the processing unitThe

Pressure transmitter D91 (Profibus PA) 35Notes

ISO 9001All statements concerning scope of delivery, application, practicaluse and operating conditions of the sensors and processing sys-tems corresp

4 Pressure transmitter D91 (Profibus PA)Product description1 Product description1.1 Function and configurationD91 pressure transmitters, which incorpo

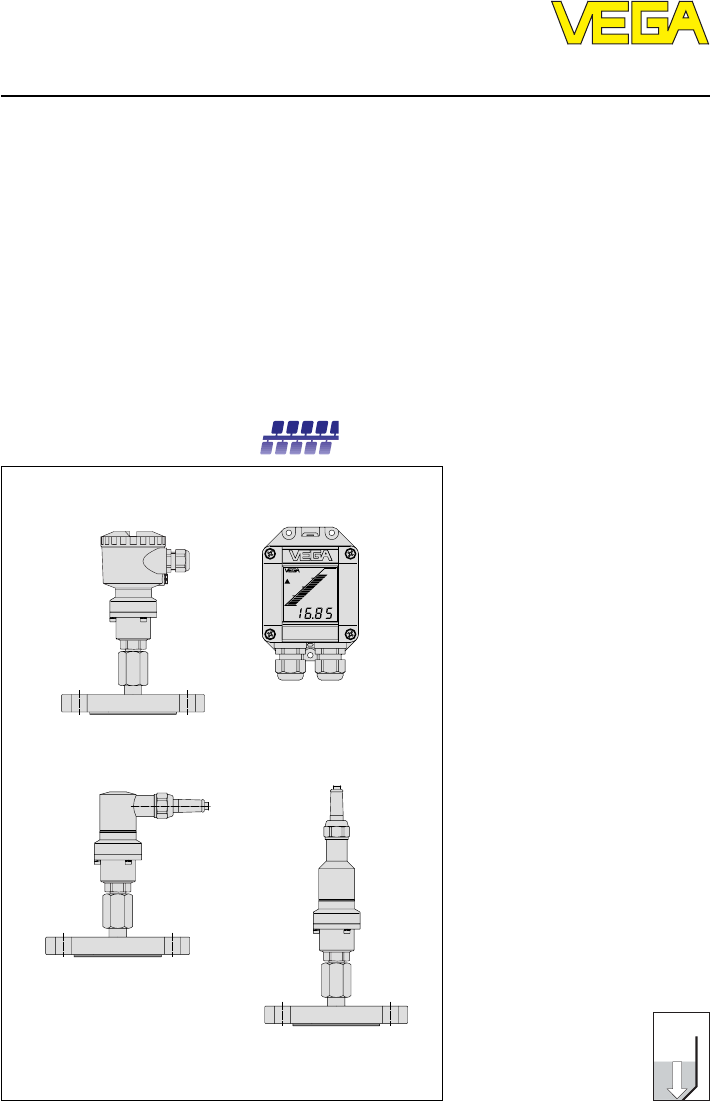

Pressure transmitter D91 (Profibus PA) 51.2 Types and versionsHousing with terminalsCable outlet axialCable outlet lateralPlug connection lateralProfi

6 Pressure transmitter D91 (Profibus PA)Product descriptionNominal measuring range Gauge pressure resistanLow pressure resistanceGauge pressure0…0.4 b

Pressure transmitter D91 (Profibus PA) 71.3 Technical dataMechanical dataTransmitter materials, wetted partsProcess connection stainless steel 1.4571D

8 Pressure transmitter D91 (Profibus PA)Product description1)The use of a properly fitting cable seal in the cable connection is necessary for maintai

Pressure transmitter D91 (Profibus PA) 91)In compensated temperature range of 0°C … +80°C, reference temperature 20°C.2)Acc. to IEC 770, item 6.1.2 re

Weitere Dokumente für Ausrüstung Vega D91 Profibus PA

(16 Seiten)

(16 Seiten) (68 Seiten)

(68 Seiten) (28 Seiten)

(28 Seiten) (44 Seiten)

(44 Seiten) (4 Seiten)

(4 Seiten) (4 Seiten)

(4 Seiten)

Kommentare zu diesen Handbüchern